Services > Casing and Tubing Running Services > Casing Hardware Services

Casing and Tubing Running Services

Casing and Tubing Running Services

Casing Hardware Services

TOS is offering DAVIS-LYNCH, inc. products in Tunisia

Overview of Products Offred through TOS by Davis-lynch, Inc

- Cementing Float Equipment.

- Inner-string Cementing Float Equipment.

- Anti-rotation Float Equipment and Cementing Plugs.

- Conductor Casing Hangers and Landing Rings (offshore markets).

- Specialty extended reach casing equipment

- Casing hardware inclusive of: Centralizers, Turbolizers, Rigid Centralizers, Stop Collars, and Cement Baskets.

- Mechanical and Hydraulic Opening Stage Cementing Collars.

- Combination Packer Stage Cementing Collars.

- Integral Casing Packers.

- Casing Fill and Circulate Tools.

Quality Control/Assurance Program

• Equipement is all dherenced to ISO 9001:2000 standards for design criteria, manufacturing procedures, product and material tracking, inspection procedures, design validation and customersatisfaction.

• Valid API Specifications or recommendations.

- API Casing Specification 5CT.

- API RP 10F Float Equipment recommended practices for testing.

- API specification 10D for casing centralizers.

Conventional Type Cementing Shoes

- Type 500 Float Shoes.

- Type 501 Down Jet Float Shoes.

- Type 501DV Double Valve Down Jet Float Shoes.

- Type “S” Set Shoes.

- Ribbed Down-Jet Float Shoe.

- Needle Nose Float Shoes.

- Eccentric-nose Float Shoes.

- Ream Master Float Shoes.

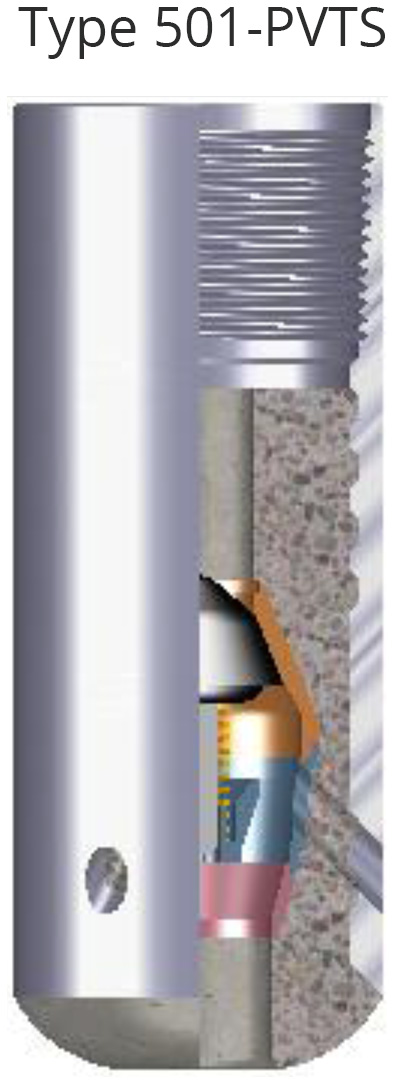

Type 500 Float Shoes

- Rounded design of concrete nose assists in guiding string to bottom.

- Concrete internals with single PVTS spring assisted back-pressure valve.

- PVTS valve tested to exceed API-RP 10F for category III-C.

- Valve comprised on mostly non-metallic internals.

- Safely drilled out with all bit types including PDC bits.

- Typically used on intermediate and production casings, at times on surface casings.

Type 501 Down Jet Float Shoe

- Same features/benefits as Type 500 Float Shoe.

- Additional benefits include drilled and angled down-jet ports that promote even distribution of fluid exiting the shoe.

- Added assurances that string will not become plugged and assist to prevent channeling of cement exiting the shoe.

Type 501DV Double Valve Down Jet Float Shoe

- Same features and benefits as the Type 501 shoe with additional back-pressure valve.

Type S Set Shoe

- Shoe with special drillable lug nose.

- Predominate application is for liners.

- Lug nose contact with formation assists in preventing casing rotation when releasing from liners with the work string.

- Same PVTS valve internals.

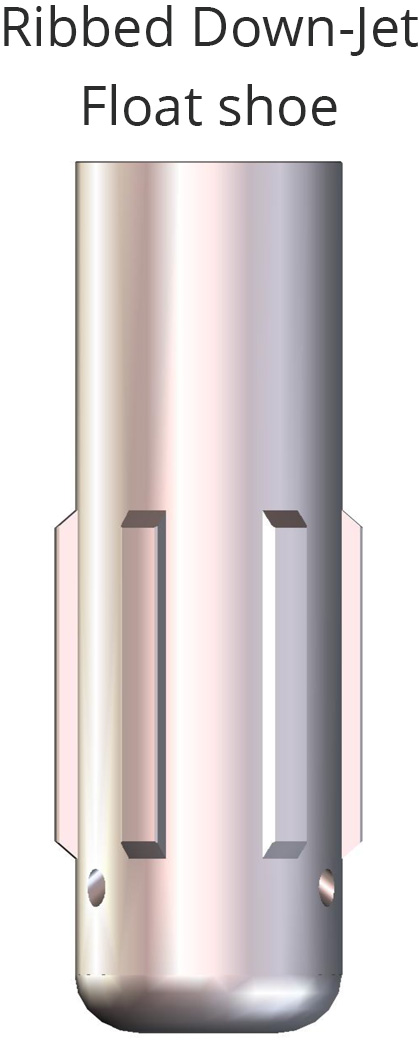

Ribbed Down Jet Float Shoe

- Stand-off ribs incorporated into the shoe.

- Built to specification.

- Same PVTS valve internal(s).

- Also available in a float collar configuration.

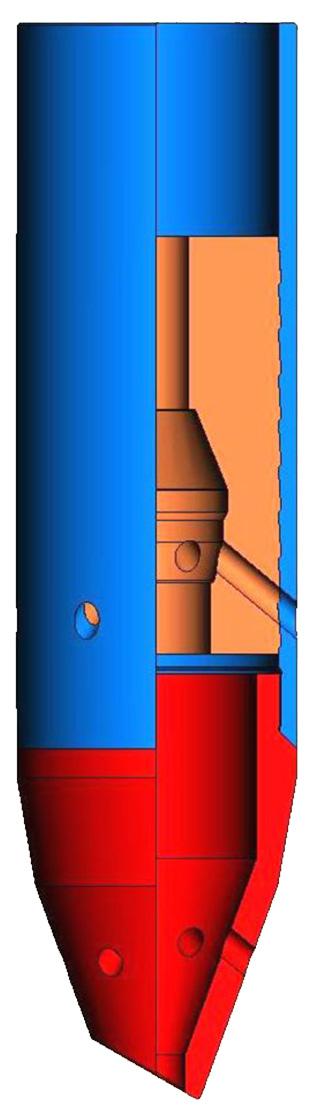

Needle Nose Float Shoe

- An aid to run casing in adverse conditions.

- Tapered nose for leading edge of casing string allows for effective running through tight spots, irregular well bores, previous casings that have been damaged etc...

- Incorporates down-jet ports.

- Nose available in aluminum or non-metallic material.

Eccentric Nose Float Shoe

- An aid to run casing in adverse conditions with off-center nose piece.

- Tapered nose for leading edge of casing string allows for effective running through tight spots, irregular well bores, previous casings that have been damaged etc...

- Incorporates down-jet ports.

- Nose available in aluminum or non-metallic material.

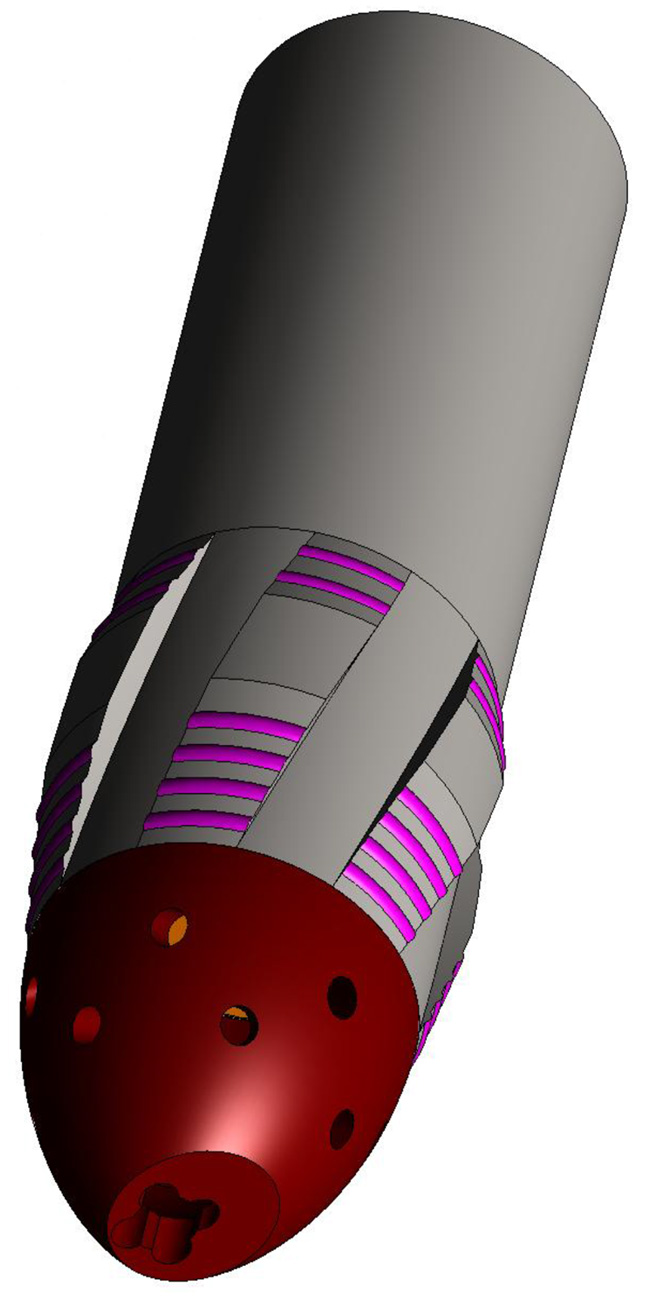

Ream Master Shoe

- Milled ribs for maximum strength.

- Non-aggressive hard-banding applied to leading and trailing shallow-angled profiles of ribs ensure that the shoe will not make new hole.

- Optimized Rib width provides full stand-off with good flow area between ribs.

- Can be supplied as a Guide Shoe (no valves), or with one or multiple back-pressure valves.

- Cast Aluminum nose material standard, easily drilled out due to numerous break points (jets) and shorter design.

- Optional composite nose material is even easier to drill out with only a 20% reduction in overall strength.

- Center hole in nose is designed to prevent drop balls from potentially sealing off thereby reducing flow area.

- Can be rotated and/or reciprocated as desired.

- Available in 3-1/2” through 20” casing sizes, with customizable rib OD’s.

Conventional Type Float Collars

- Type 700 Float Collar.

- Type 700 LAP/N Float Collar.

- Type LAP/N Top and Bottom plug.

- Type 713-MP Multi-Purpose AutoFill Float Collar.

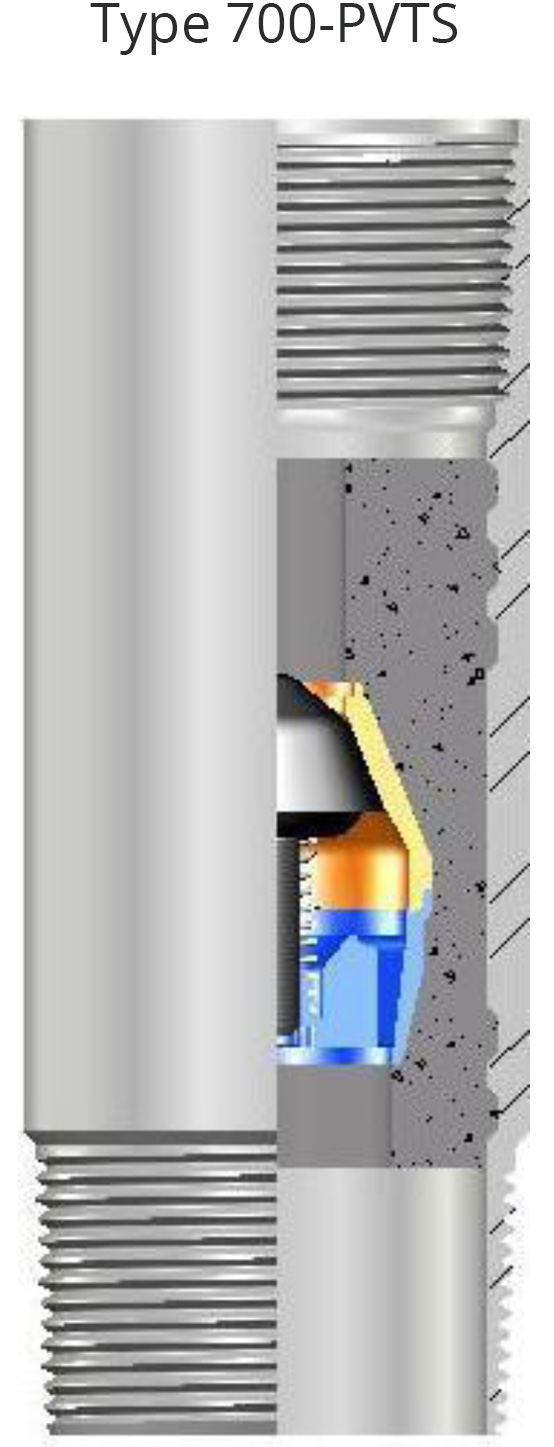

Type 700 Float Collar

- Flat concrete surface for landing and sealing cementing plugs.

- Concrete internals with single PVTS spring assisted back-pressure valve.

- PVTS valve tested to exceed API-RP 10F for category III-C.

- Valve comprised on mostly non-metallic internals.

- Safely drilled out with all bit types including PDC bits.

- Typically used on intermediate and production casings, at times on surface casings.

Type 700 Lap/N Float Collar

- Same features/applications as Type 700 Float Collar.

- Additional benefit of having an insert molded into collar to receive lock-down/anti-rotation plugs.

- Typically used when PDC bits will be employed for drill out.

- Designed for plugs to latch-down so that plug separation is prevented when casing pressure is released.

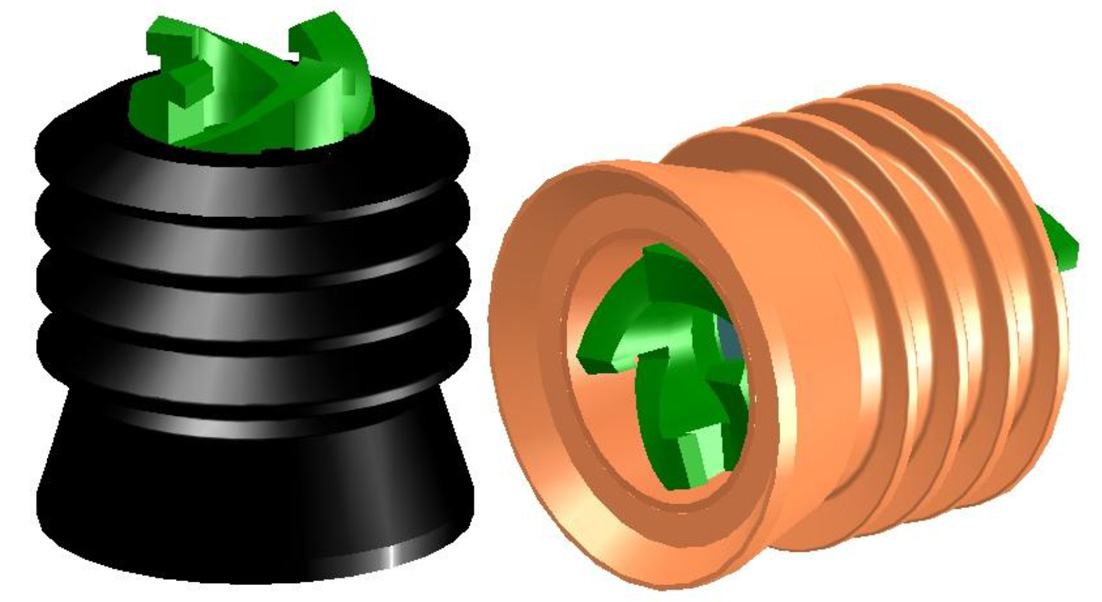

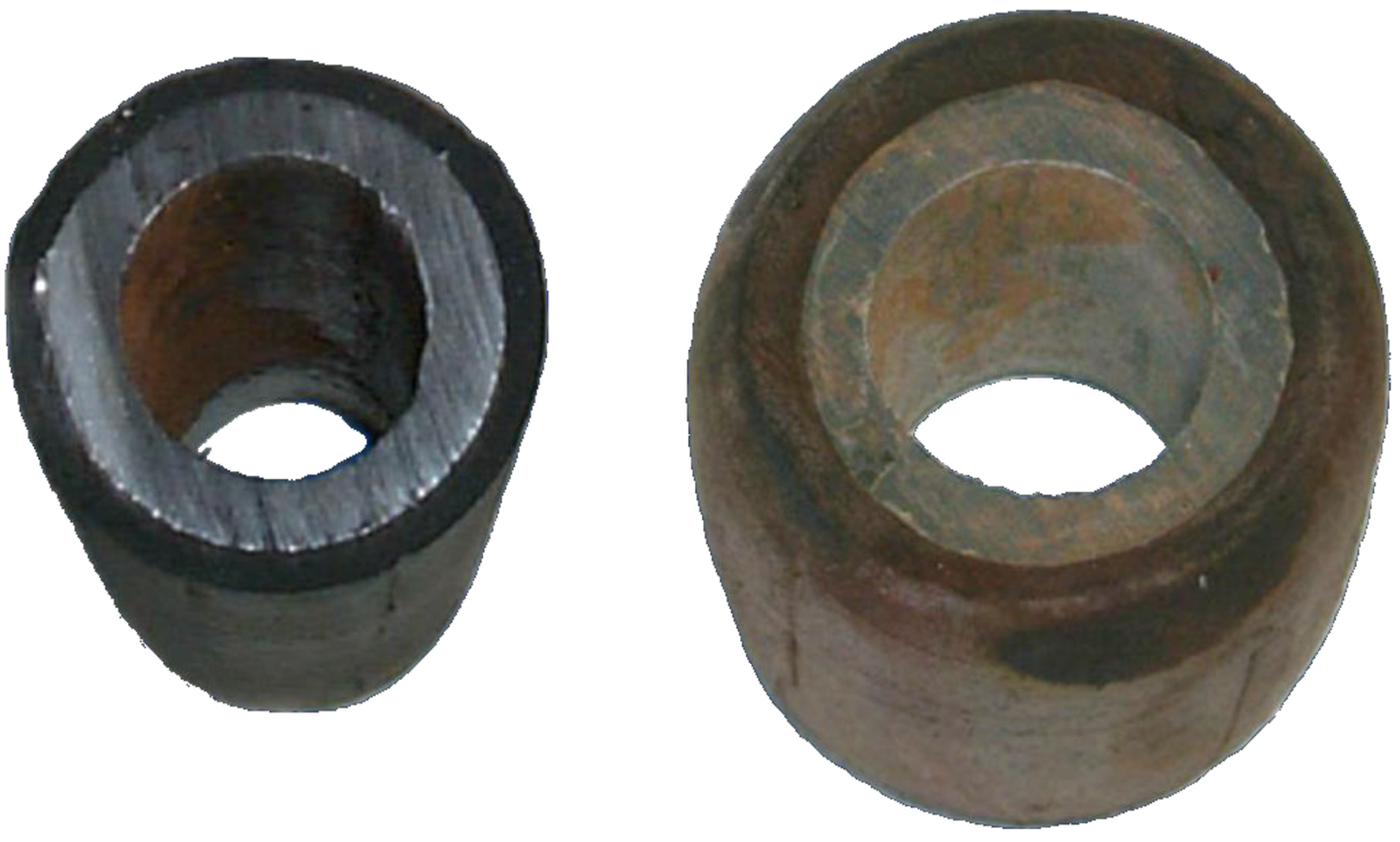

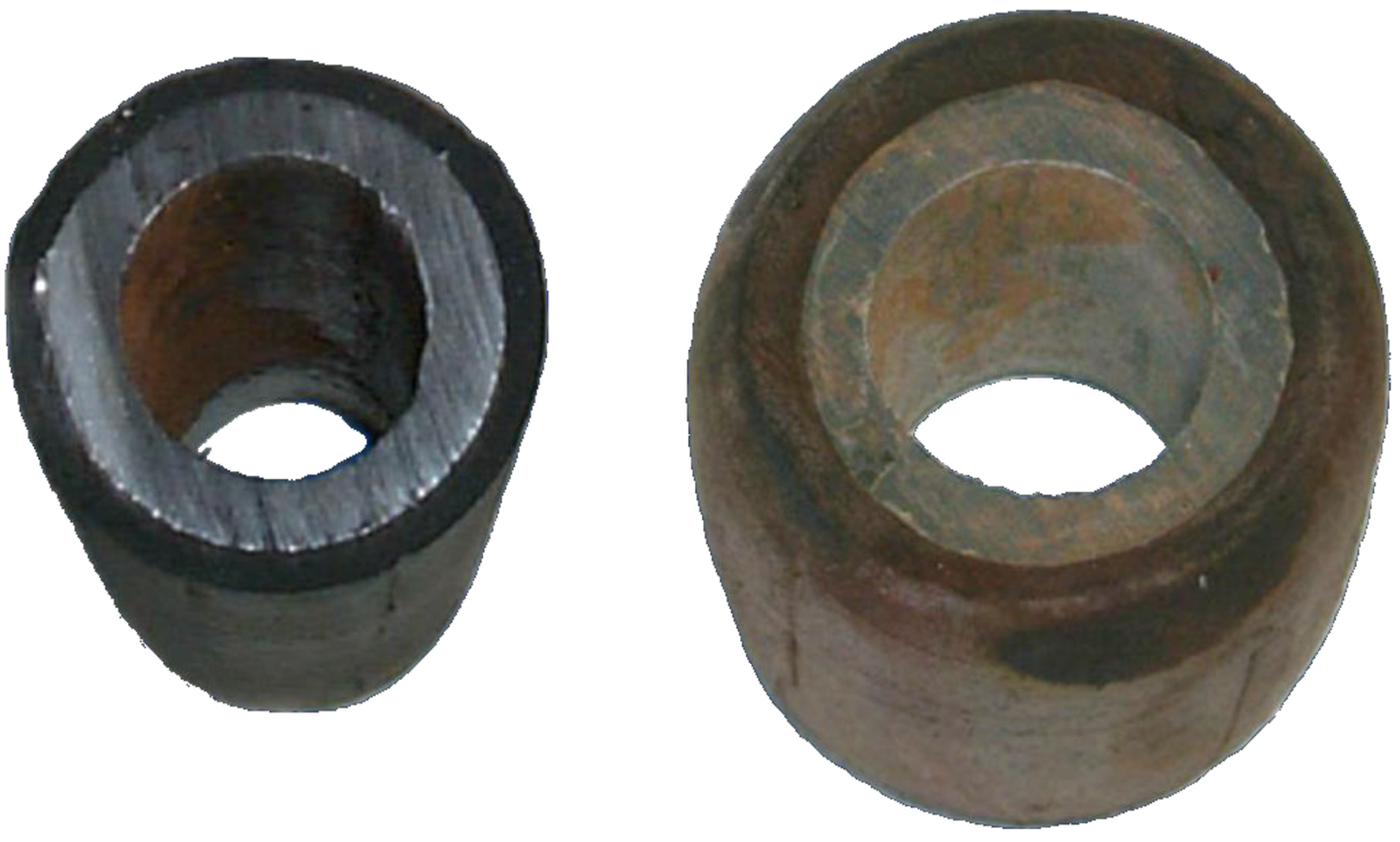

Type Lap/N Top and Bottom Plugs

- Plugs lock against rotation inside type 700 LAP/N collar during drill out.

- Plugs lock against upward movement to prevent them from being unseated while being drilled out.

- Typically application for PDC drill out.

Type 713-MP Multi-Purpose AutoFill Float Collars

- Reduces surge pressures while running casing or liner in tight holes.

- Casing fills automatically while running.

- Reliable double-valve flapper design with large inlet.

- lappers protected from debris while running in hole, not exposed to flow until after conversion.

- Adjustable conversion pressure from 300 psi to 3200 psi.

- Drop ball-seat size is adjustable from 1.50” to 4.50” OD drop balls.

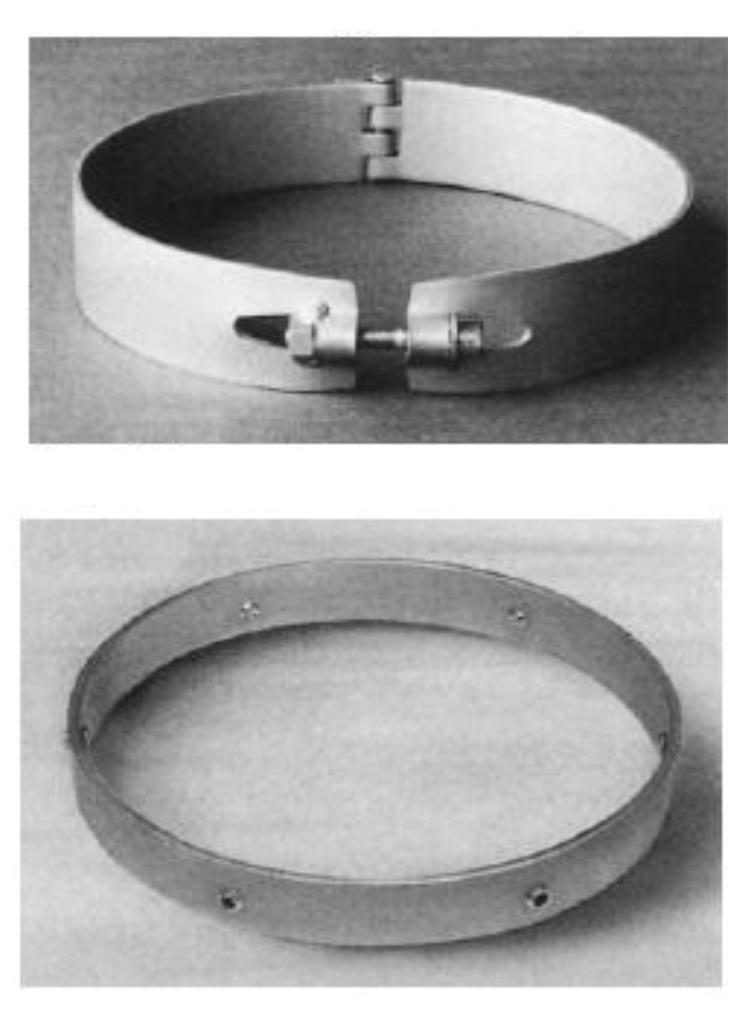

Casing Hardware

- Hinged non-welded Centralizers.

- Hinged non-welded Turbolizers.

- Slip-on close tolerance Centralizers.

- Cement Baskets.

- Stop Collars.

- Solid Body Rigid Centralizers.

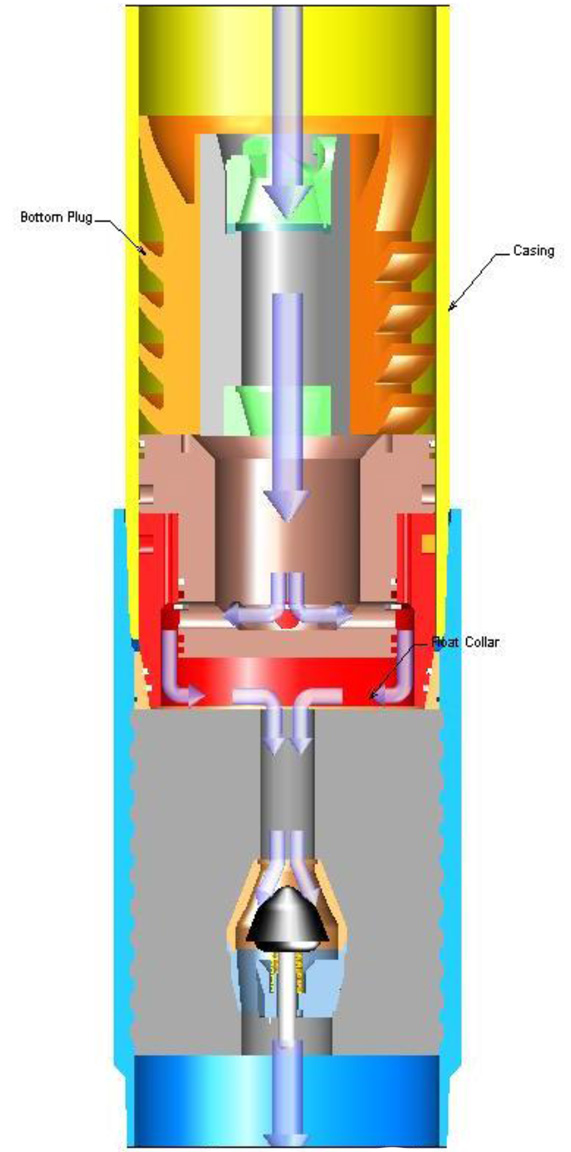

Davis Flotation Collar Run-In Position

- Bottom portion of casing is run dry (not filled with fluid), with Davis Flotation Collar installed at desired depth. Casing above the DFC is filled with drilling fluid as casing run continues to desired depth.

Davis Flotation Collar Open Position (Fluid-Air Swap)

- Casing pressure is increased until the opening sleeve shifts down to permit fluid and air to swap. After a fluid stabilization period, the casing is filled with drilling fluid.

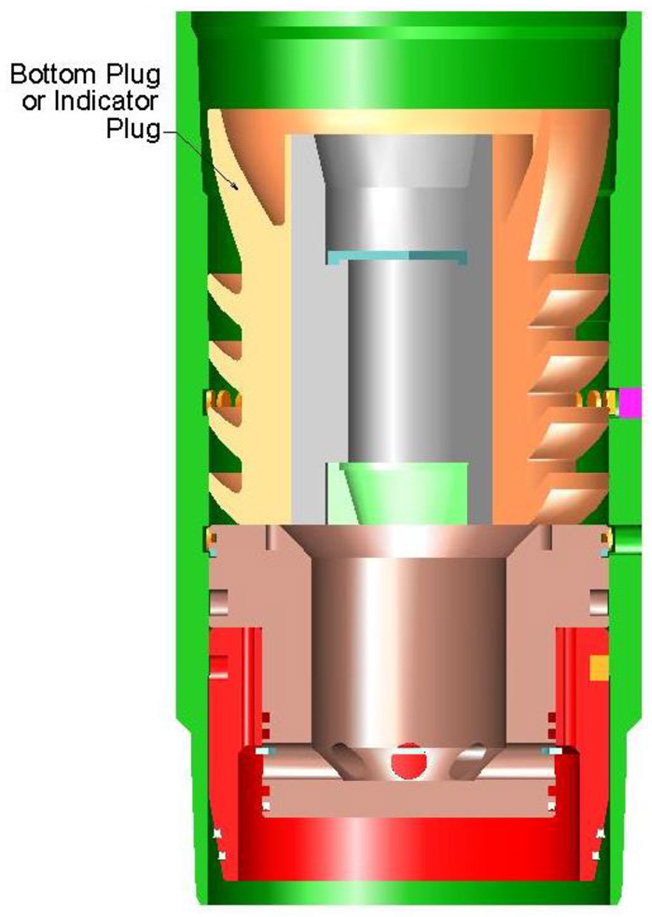

Davis Flotation Collar Bottom Plug or Indicator Plug

- Bottom cementing plug or Indicator plug is launched ahead of cement. After landing on the bottom sleeve, it pushes both DFC sleeves ahead of the cement to the float collar below.

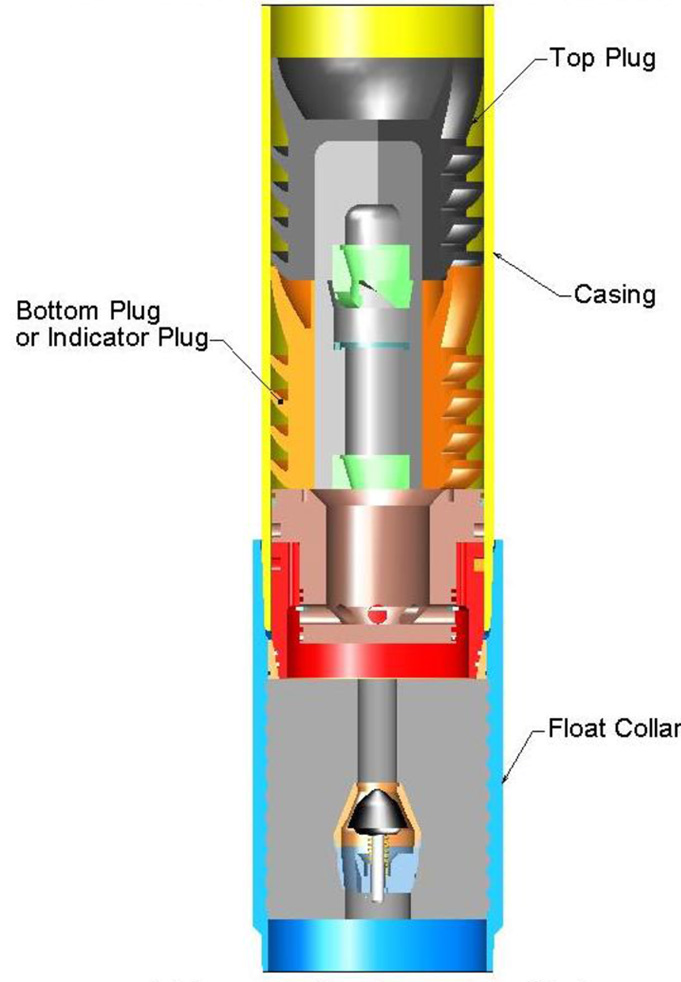

Davis Flotation Collar Sleeves and plug land on float collar

- Bottom cementing plug and sleeves land and seal on the float collar. Bottom cementing plug ruptures, and cement is pumped through and out of the float equipment.

Davis Flotation Collar Top plug lands on float collar

- Top cementing plug seals and locks on bottom cementing plug/DFC assembly at the float collar.

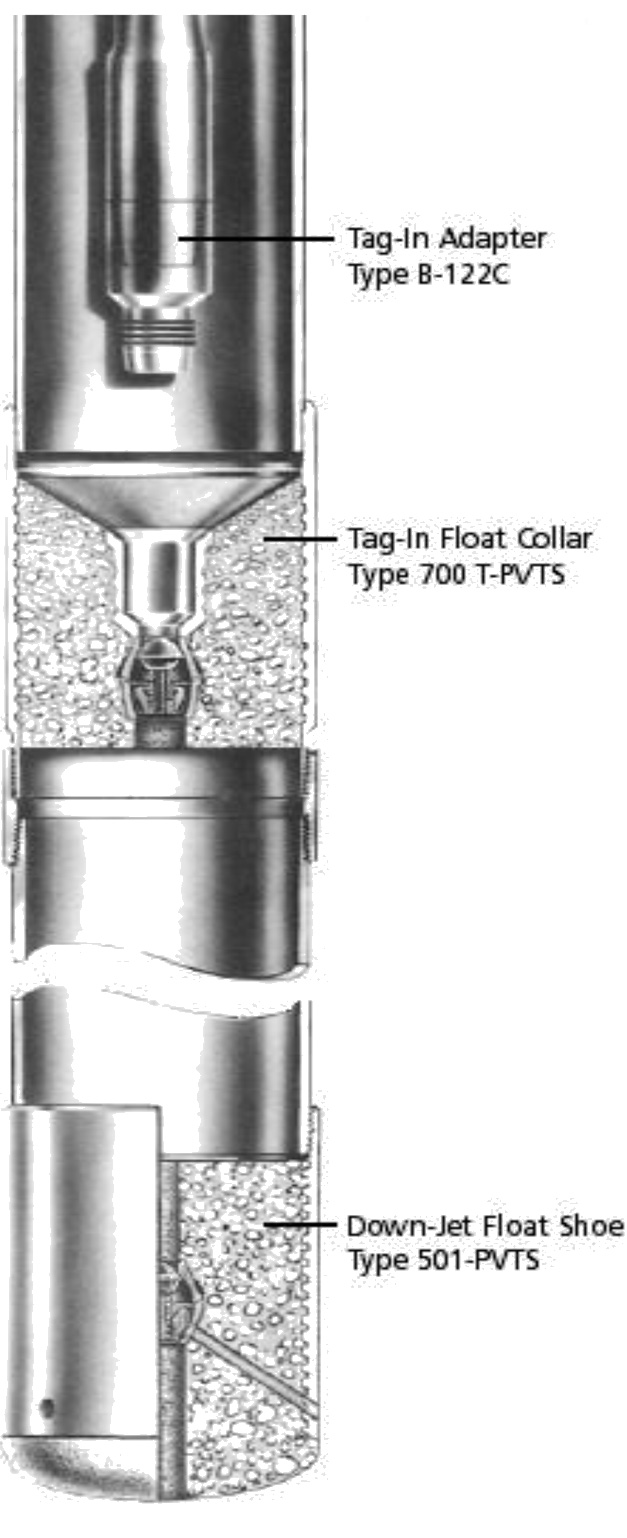

Inner-string Cementing Equipment

- Type 700 T Tag-in float collar.

- Type 501 DVT Double Valve Tag-in Float Shoe.

- Type B-122 C Tag-in Adapter.

Type 700 T Tag-in float collar

- Typically used for large diameter surface casing applications.

- Receiver built into collar that receives adapter on the bottom of drill pipe inner-string.

- Reduced displacement volumes of drill pipe versus casing.

- Reduces risk of cement contamination.

- Allows for lead cement to be pumped until surface returns are seen, then tail.

- Eliminates requirement for handling large diameter cementing heads and plugs or drilling out large diameter plugs.

Type 501 DVT Double Valve Tag-in Float Shoe

- Same application benefits as type 700 T Tag-in collar.

- Configuration with receiver for adapter incorporated into shoe.

- Double PVTS valve assembly for redundancy to assure cement is retained in the annulus.

Type B-122 C Tag-in Adapter

- Available in sizes 2-7/8” tubing thru 7-5/8” casing.

- Erosion-resistant coating for heavy drilling fluids.

- Back-pressure rating to 10,000 psi.

- Drillable with mill-tooth rock bit, some success with PDC bits .

Hinged Non-Welded Centralizers

- Designed to meet or exceed performance requirements of API Spec 10D for starting and restoring forces.

- Davis “only” provides bow spring centralizers to the API spec-No economy line.

- Unique interlocking adjoinment between end collar and bow spring.

- Multiple bow heights available to meet all hole size requirements.

- End collar hinges folded inward to reduce risk of collar stretch

Slip-on Close Tolerance Centralizers

- Meet or exceed API spec 10D.

- Run in close tolerance applications mainly on liners.

- Can be run in clearances as small as 7/8” over casing OD.

- Can be run with set screws incorporated or between stop devices for rotation.

Cement Baskets

- Simple, economical annular pack-off.

- Commonly used in multi-stage cementing applications.

- Available for all casing sizes.

- Overlapping steel petals allow for cement flow-by from below, but help prevent cement from falling from above.

Solid Body Rigid Centralizers

- Centralization through positive or rigid centralization.

- Aid for mud wash and removal of gelled mud.

- Generates turbulence around casing for bonding of cement.

- Can be made from steel or aluminum.

Spiromizers

- Solid-Body Cast Steel Centralizer, no welding.

- High-strength alloy steel.

- Spiral ribs generate turbulence around casing for bonding of cement.

- Self-cleaning blade design.

- Aid for mud wash and removal of gelled mud.

- Maximized fluid flow.

- Resistance to wear and abrasion.

Stop Collars

- Hinged “friction” type with bolt assembly suitable for most applications.

- Slip-On set screw type for premium applications when enhanced holding forces are required.

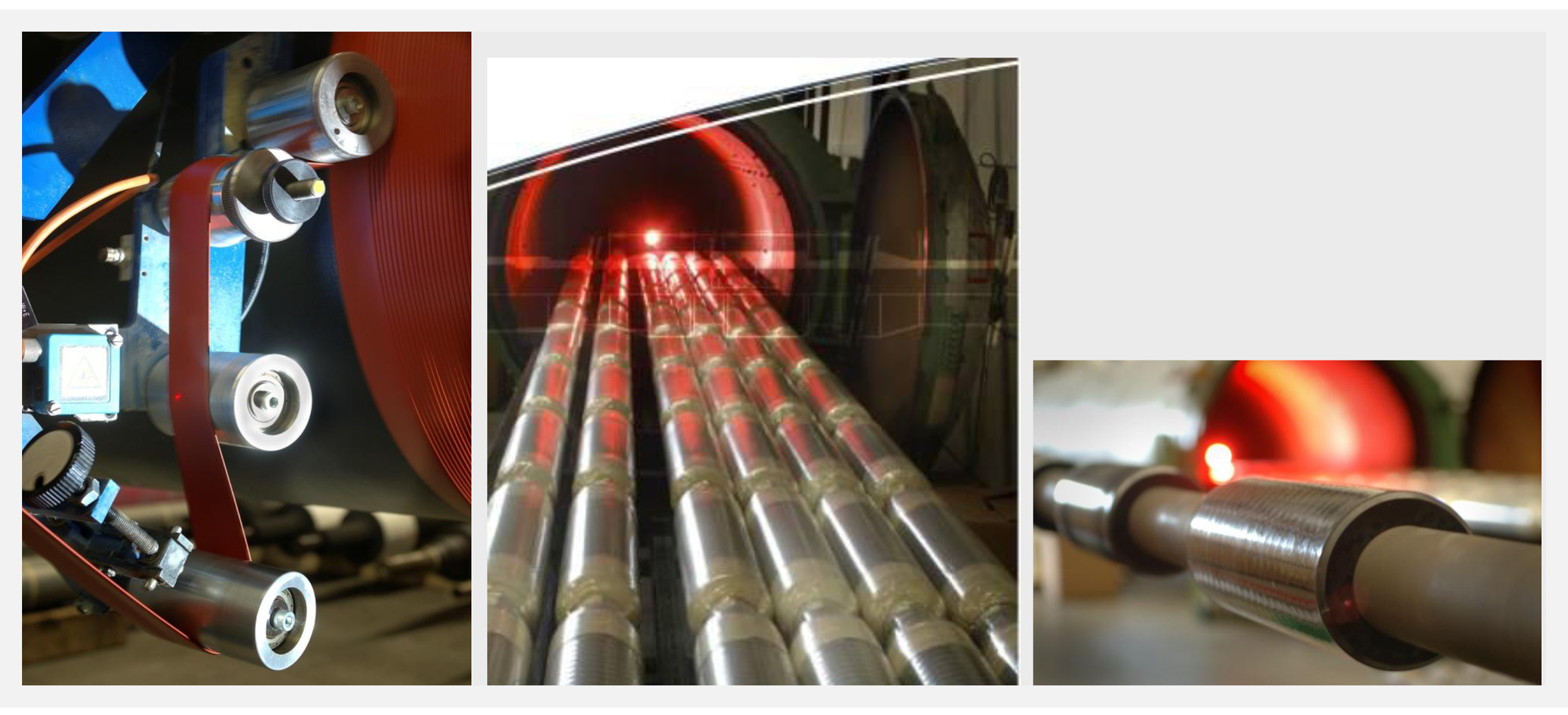

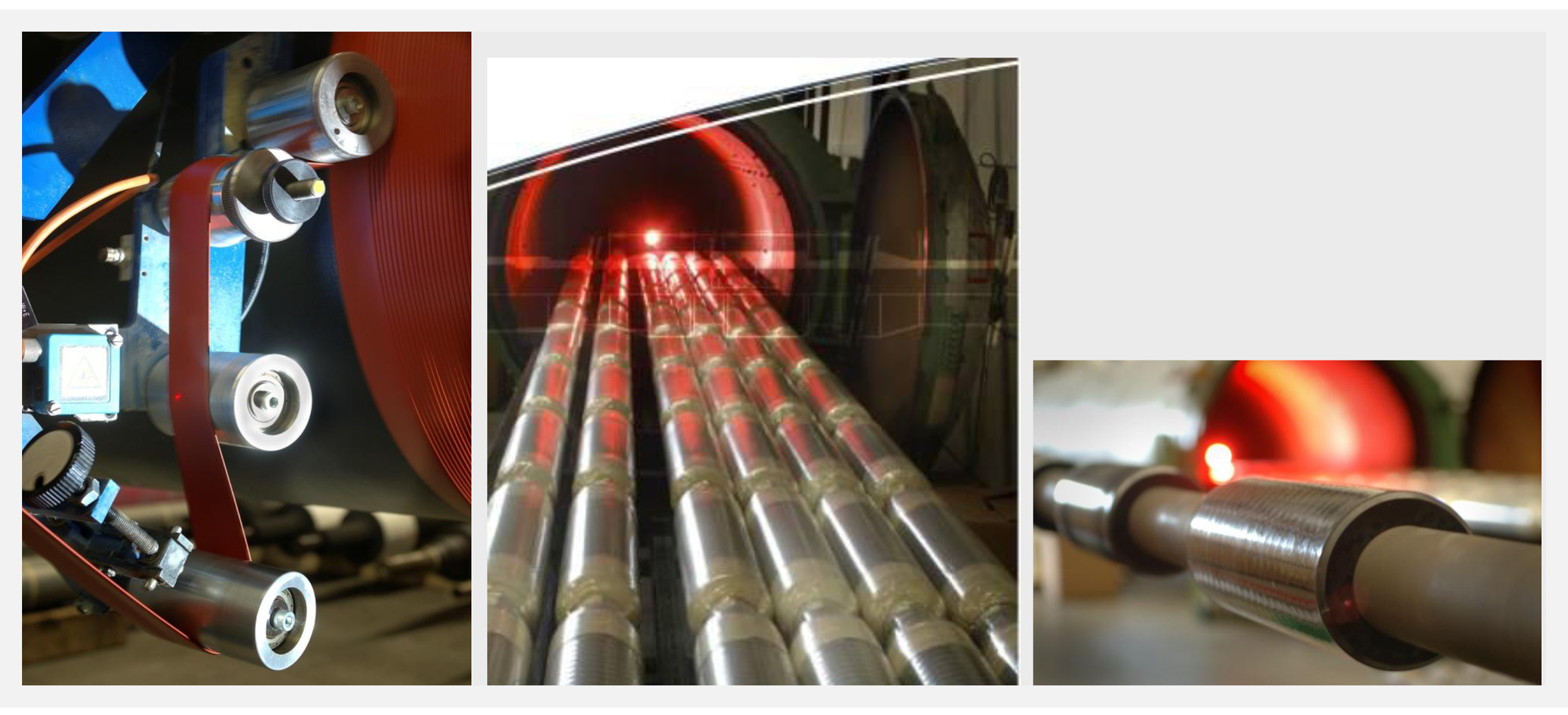

CentraLaser Centralizers

- Rugged Non-weld One-Piece Centralizer.

- Cut out of seamless pipe with a laser.

- Run in close tolerance applications mainly on liners.

- Can be run in clearances as small as 3/8” over casing OD.

- Can be anchored to casing with epoxy

- Can be anchored to casing with Spray-metal stop devices

Solid Body Rigid Centralizers

- Centralization through positive or rigid centralization.

- Aid for mud wash and removal of gelled mud.

- Generates turbulence around casing for bonding of cement.

- Can be made from steel or aluminum.

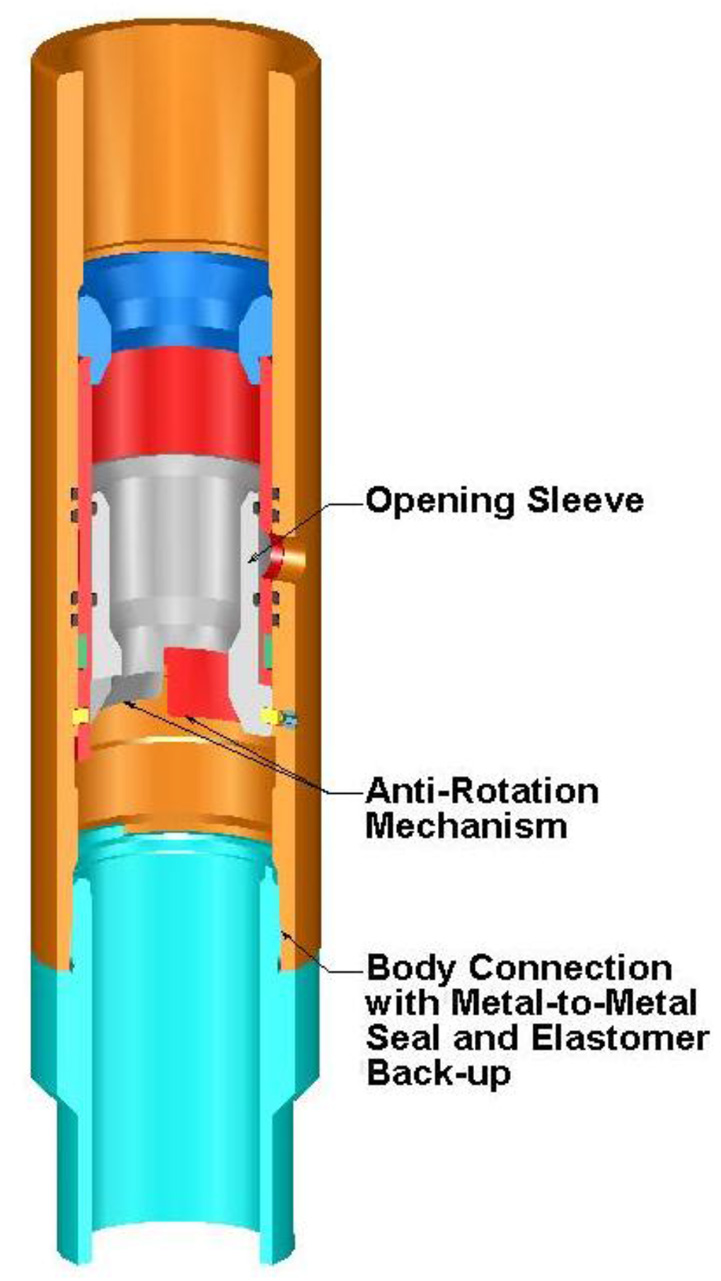

Multi-Stage Cementing Equipment/Inflatable Packers

- Type 778-MC Mechanical Opening Stage Cementing Collar.

- Type 777-HY Hydraulic Opening Stage Cementing Collar.

- Type 778-100 Packer Stage Cementing Collar.

- Type 100 Integral Casing Packers.

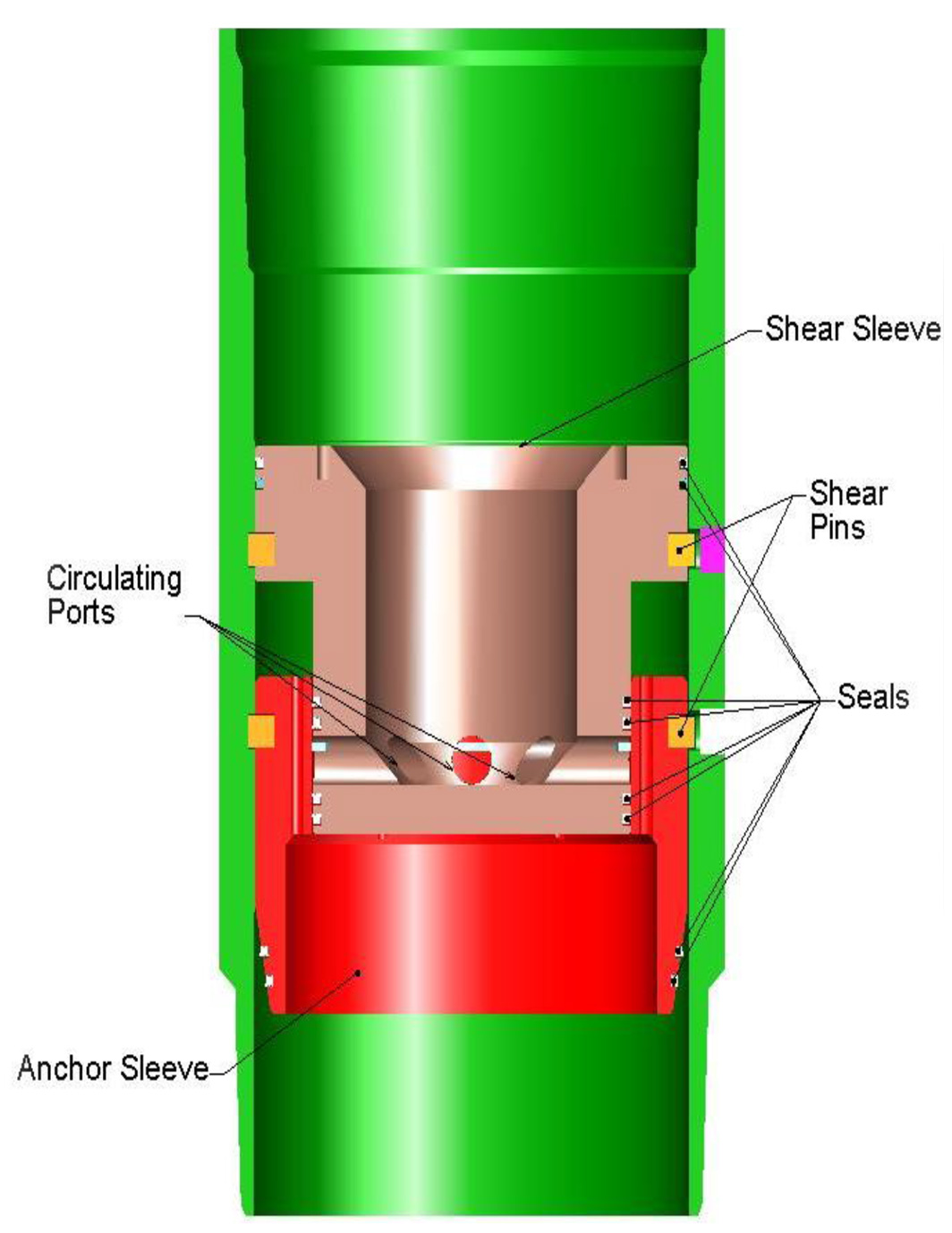

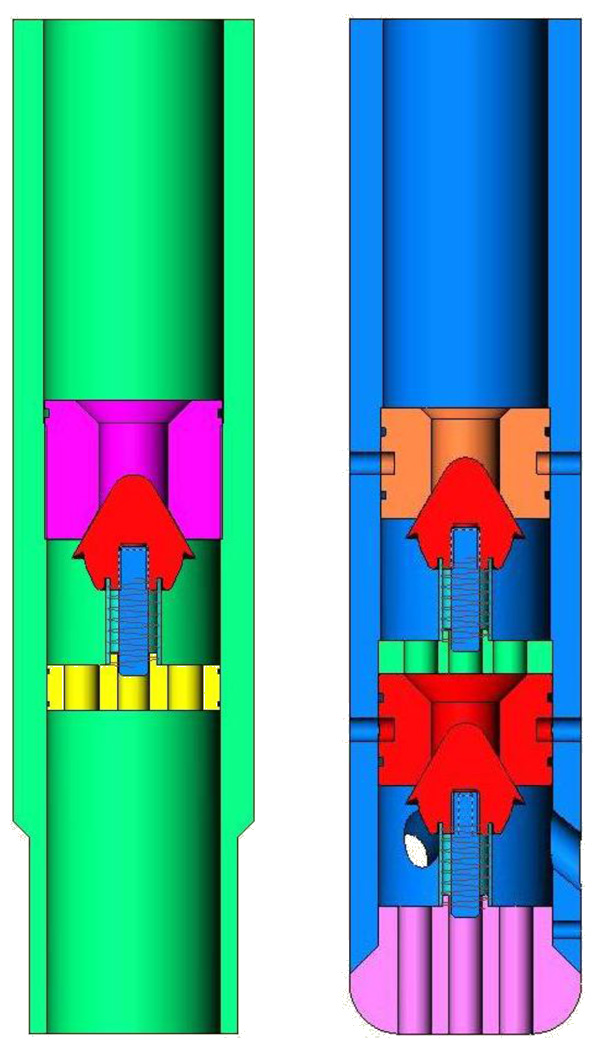

Type 778-MC Mechanical Opening Stage Cementing Collar

- Available for all casing sizes from 2 7/8” through 20”.

- Available for two or three stage cementing applications.

- Only one internal connection that effects a metal to metal seal and engages a back-up elastomer seal.

- Single entry port for installing shear pins.

- Seals providing internal and external integrity are housed in the tool body and remain stationary throughout operation of the tool.

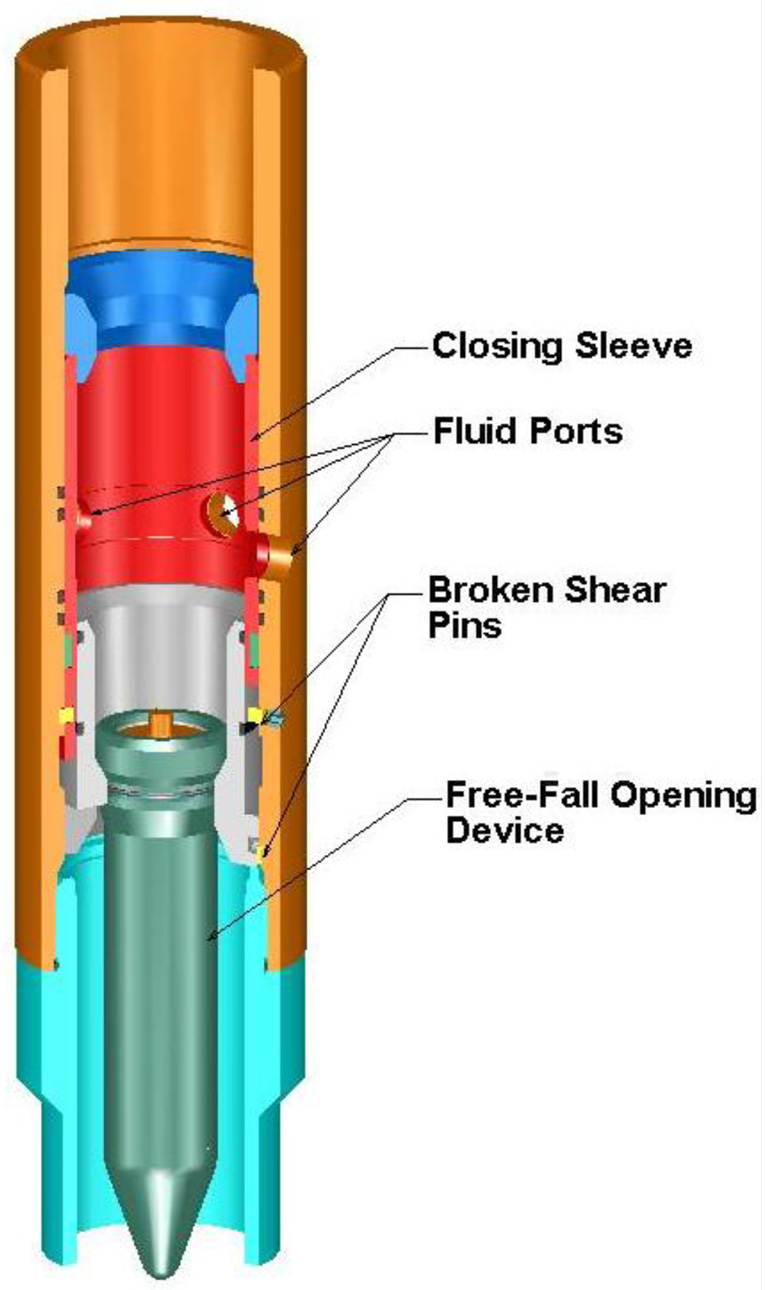

Type 778-MC Mechanical Opening Stage Cementing Collar-Open Position

- Tool opened with a free fall opening devices dropped from surface.

- 4-1” ports for flow area through sizes 4 ½”-5 ½”.

- 6-1 1/8” ports for flow area through sizes 7”-13 3/8”.

- 10-1 1/8” ports for sizes 16” and larger.

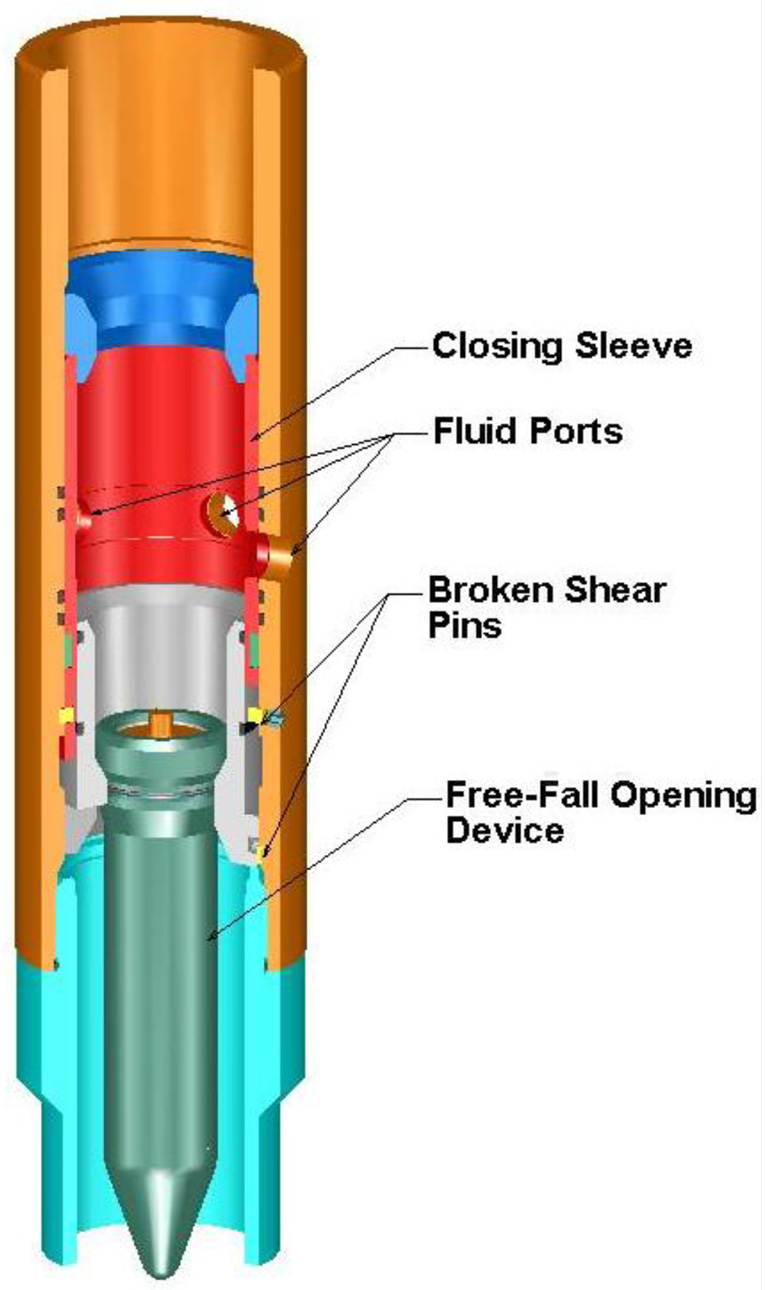

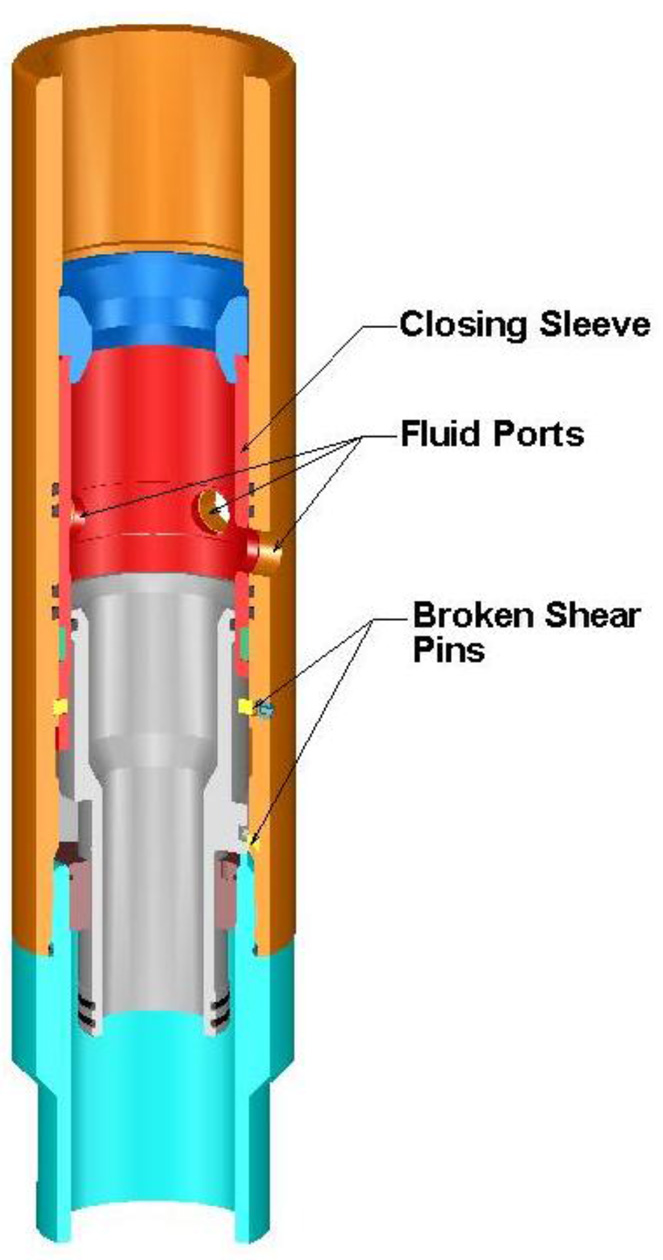

Type 778-MC Mechanical Opening Stage Cementing Collar-Closed Position

- Tool opened with a free fall opening devices dropped from surface.

- 4-1” ports for flow area through sizes 4 ½”-5 ½”.

- 6-1 1/8” ports for flow area through sizes 7”-13 3/8”.

- 10-1 1/8” ports for sizes 16” and larger.

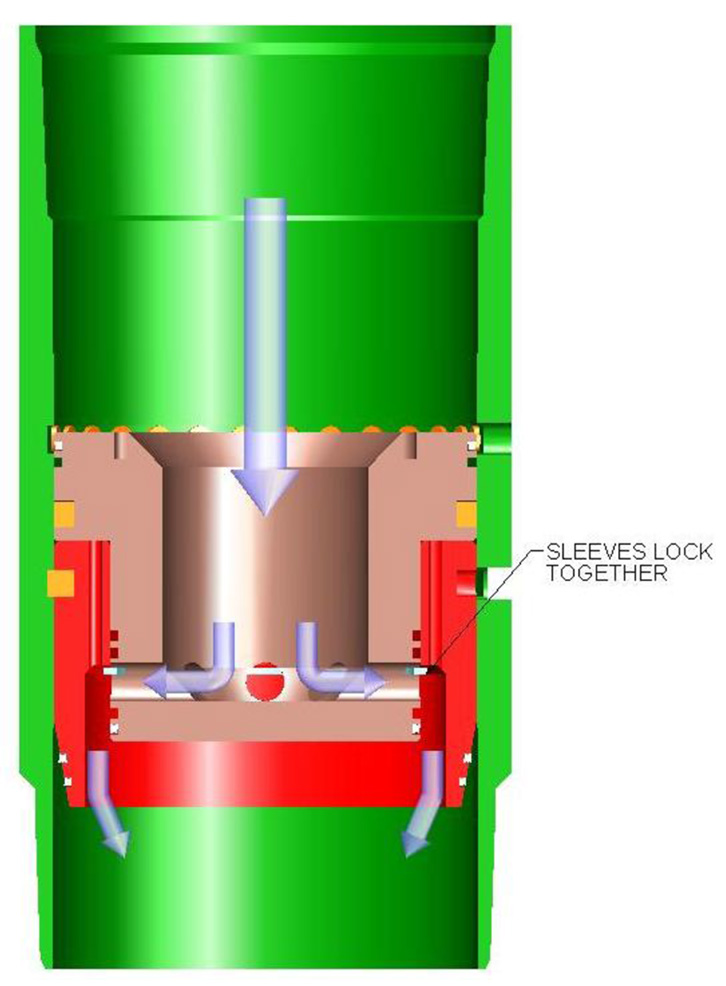

Type 778-MC Mechanical Opening Stage Cementing Collar-Closed Position

- Closed with displacement plug.

- Closing sleeve held closed with internal lock ring.

- Sleeves lock against rotation for easy drill out.

- Minimal amounts of rubber and aluminum are materials encountered during drill out.

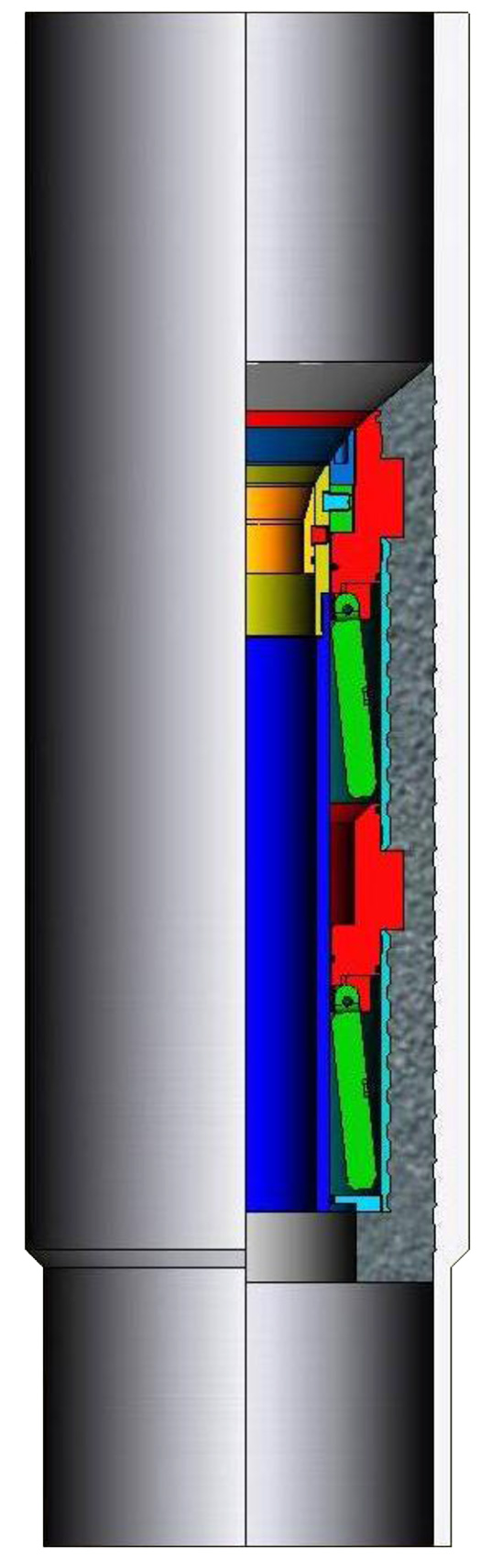

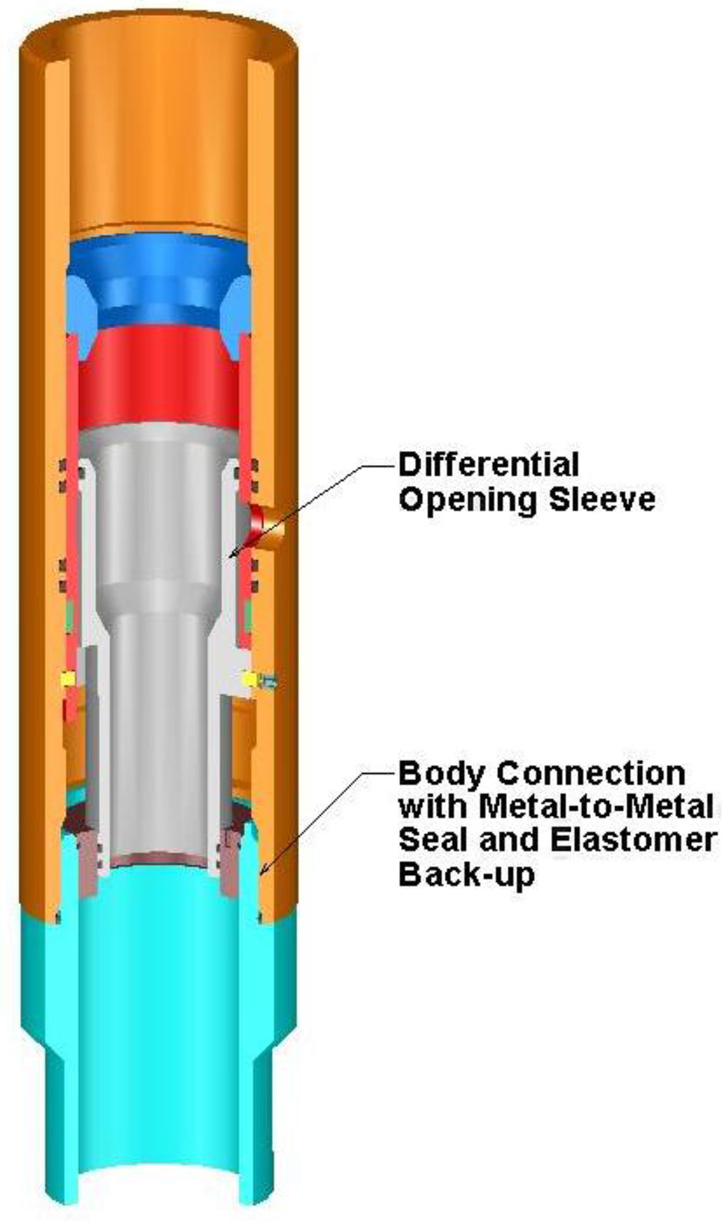

Type 777-HY Hydraulic Opening Stage Cementing Collar

- Typical for applications in deviated wells greater than 30 degrees.

- Additional applications for liners and deeper stage collar setting depths.

- Same features as Type 778-MC stage collar for closing, drill out, and integrity.

Type 777-HY Hydraulic Opening Stage Cementing Collar-Open Position

- Differential area on opening sleeve device required.

- Same flow areas as Type 778-MC.

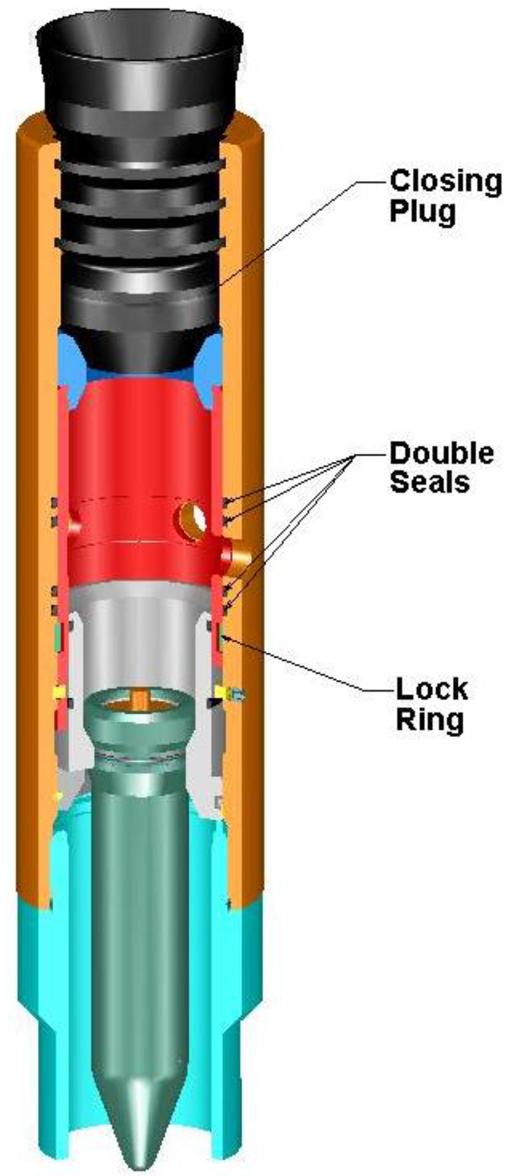

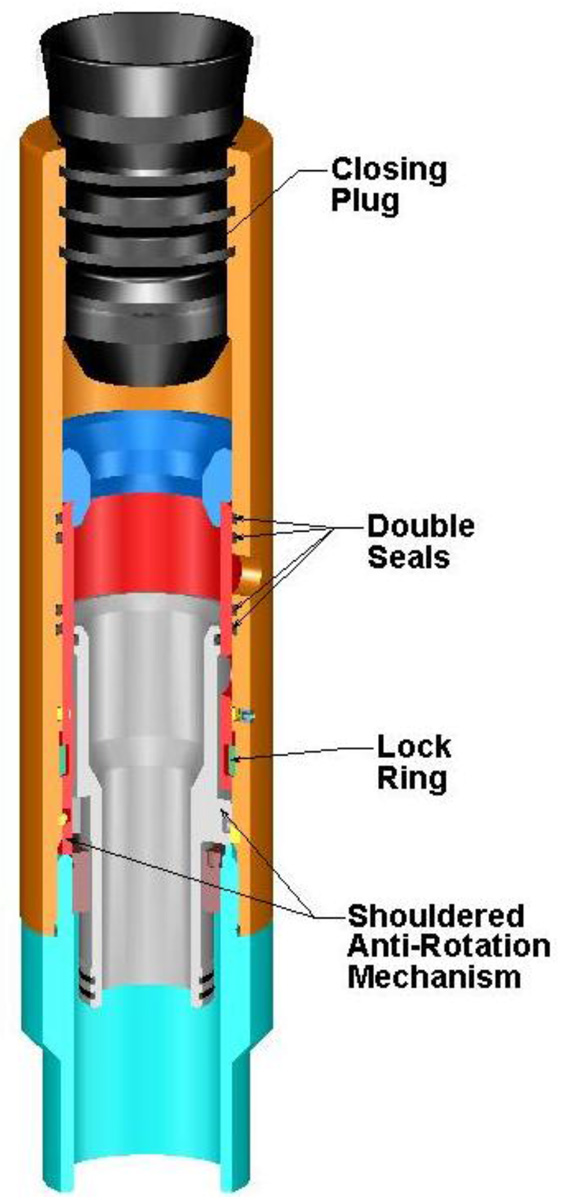

Type 777-HY Hydraulic Opening Stage Cementing Collar-Closed Position

- Closed with displacement plug.

- Closing sleeve held closed with internal lock ring.

- Sleeves lock against rotation for easy drill out.

- Minimal amounts of rubber and aluminum are materials encountered during drill out.

Type 100 Integral Casing Packers

- Available in sizes 3 ½” thru 22”.

- Inflation valves are functioned by differential pressure.

- Controls wellbore migration of gas and fluid.

- Prevents unwanted water intrusion.

- Zonal Isolation.

- Used in conjunction with stage cementing collars for multi-stage cementing applications.

Type 778-100 Packer Stage Cementing Collar

- Combination Inflatable Packer/stage collar in a single unit.

- Keeps hydrostatic head of second stage cement off of first stage cement.

- Keeps hydrostatic head of second stage cement off of pressure sensitive zones below.

- Used on applications to isolate pre-drilled or slotted casing below from cement.

- Selective placement of cement across widely separated zones of interest.

- Isolates cement from gas migration and prevents problems with annular gas.

- Available with 3, 7, & 10 foot seal lengths.

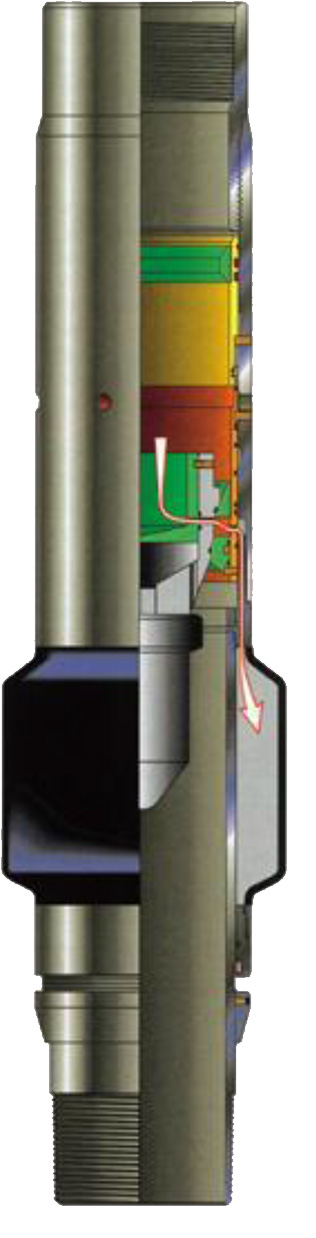

Type 778-100 Packer Stage Cementing Collar Inflating Packer

- Packer is inflated when free fall opening/inflation device is seated.

- Does not require landing first stage cementing plug.

- Inflation mechanism is not sensitive to first stage cementing/displacement pressures.

- Suitable for most applications up to 35 degrees deviation.

Type 778-100 Packer Stage Cementing Collar Cementing Ports Opened

- Additional pressure applied to inflate/opening device opens cementing ports.

- Substantial flow through area similar to stage collars after opening tool for circulating.

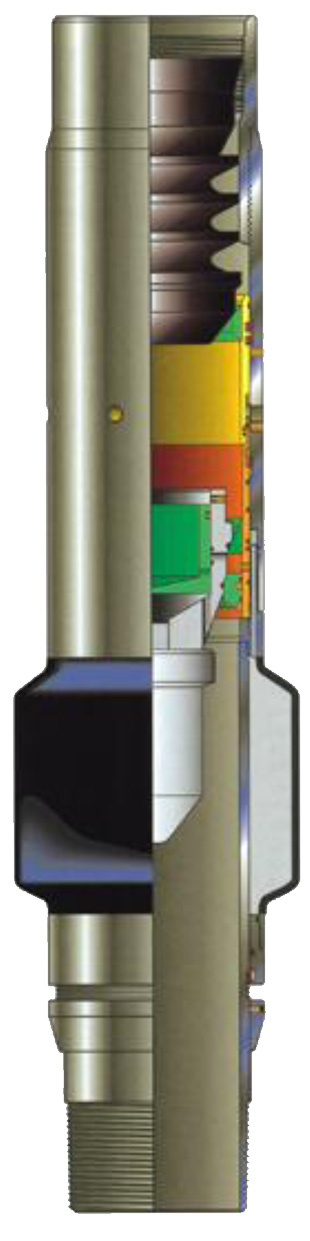

Type 778-100 Packer Stage Cementing Collar Cementing Ports Closed

- Closed with displacement plug –same as stage collar.

- Same drill out features as stage collar.

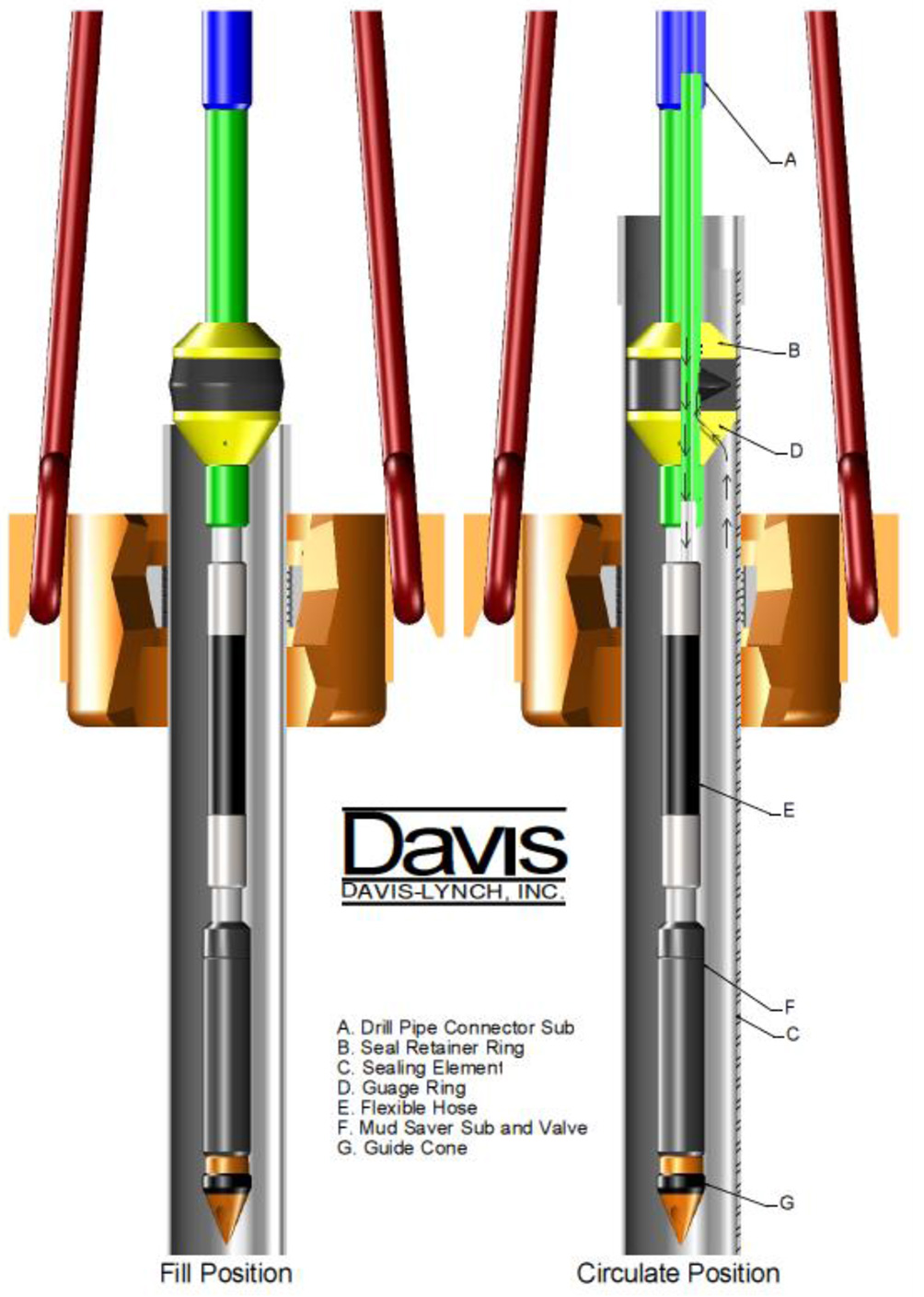

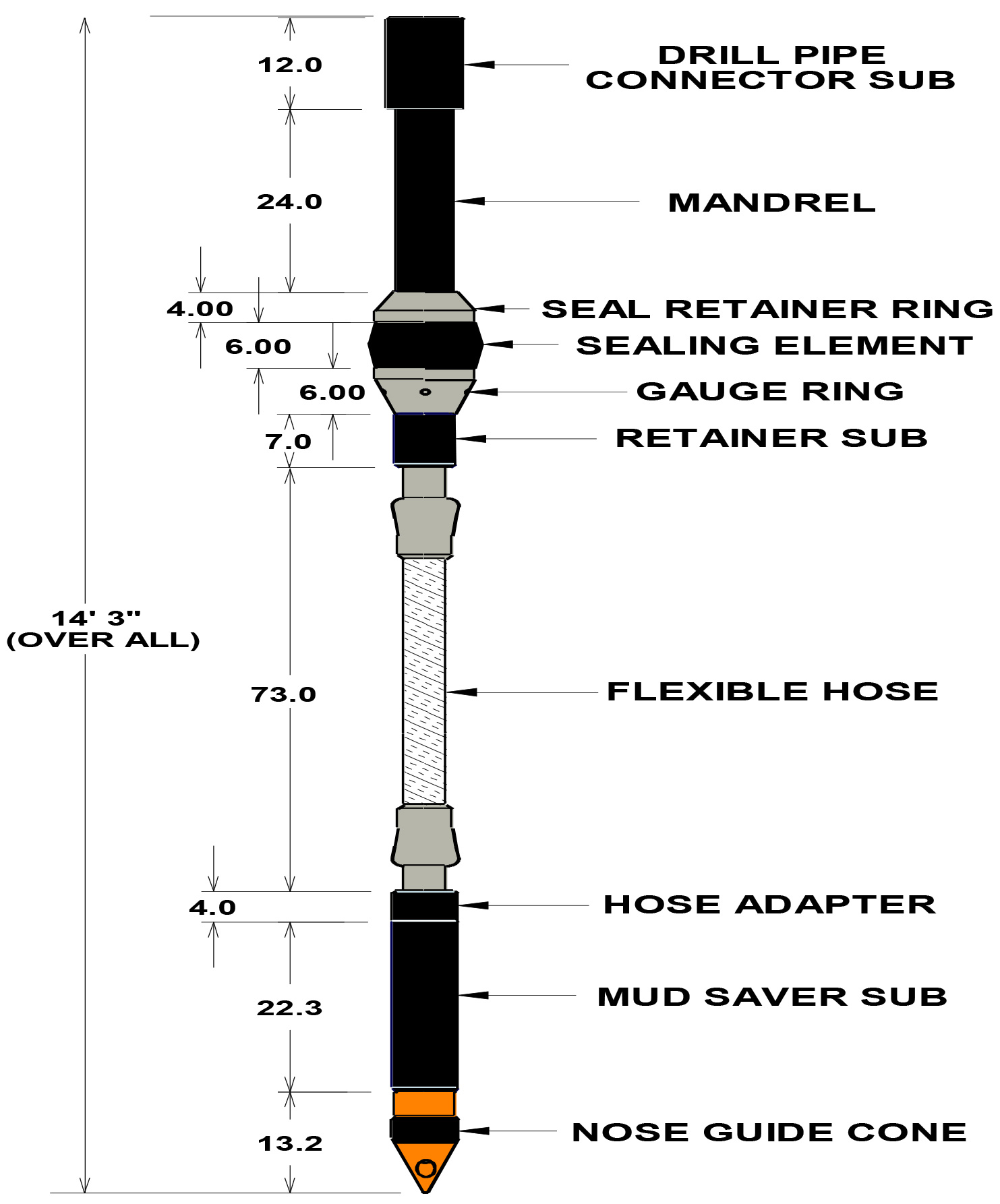

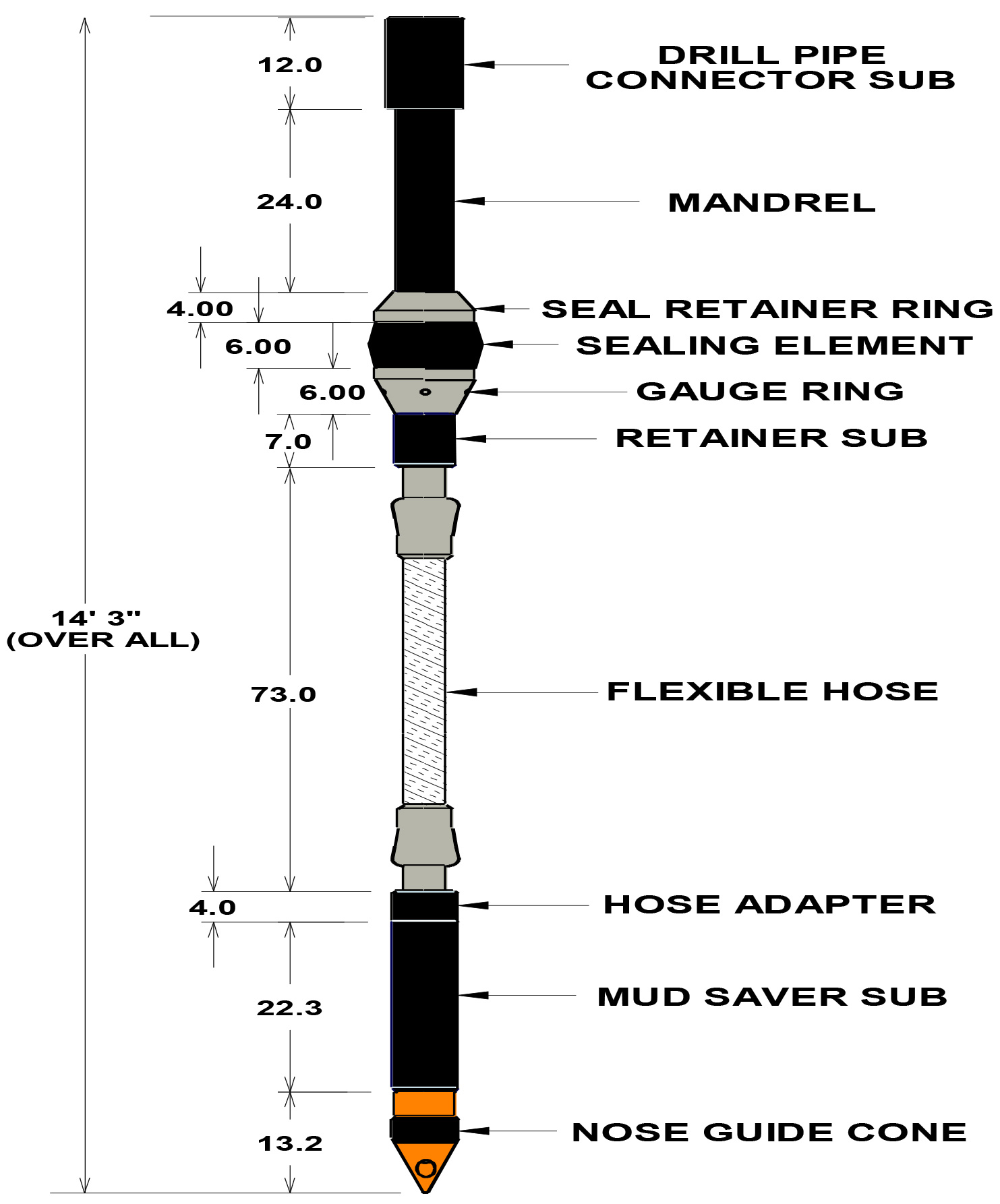

Fill and circulate Tool

- Ability to check that float equipment is functioning correctly immediately after making up into casing string.

- Time savings realized by filling each casing joint as it is run vs. shutting down to fill casing with mud hose.

- Reduces the risk of stuck casing by eliminating down-time to fill casing.

- Ability to immediately circulate casing by engaging element creates a safer working environment by eliminating the need to installa pump-in swage. Also allows for immediate well control by circulating heavier fluids as needed.

Swellfix

Manufacturer of Swellable Elastomers

rubber that swells in the presence of water or oil

Swellfix DynaForm for Cementing

- Swellable rubber bonded to the external OD of the casing.

- External rubber swells and seals where cement performance has been poor.

- Reacts to fluid ingress sealing off developing micro annuli.

- Performs well in out of gauge open hole sections.

- Installation could remove the need for cement squeeze.

- Provides significant cost savings.

- Can remove the need for a cement squeeze.

- Available for water or oil activation.

Manufacturing done in Ruma

Transport, sand blasting, coating, compounding, rolling and vulcanising

Casing and Tubing Running Services

Casing and Tubing Running Services